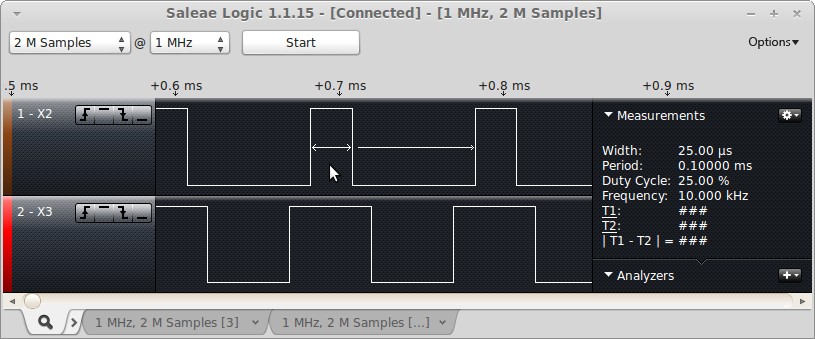

Pulse Width Modulation (PWM) @ 10 kHz on pins X2 and X3 in center mode

Pin X2 is 25% duty cycle, and X3 is 50% duty cycle.

import pyb # TIM2 runs at 84 MHz # at 20000 Hz, count runs from 0 to 4199 # In center mode, the frequency will be halved, so we'll get a 10 kHz output t2 = pyb.Timer(2, freq=20000, mode=pyb.Timer.CtENTER) ch2 = t2.channel(2, pyb.Timer.PWM, pin=pyb.Pin.board.X2, pulse_width=(t2.period() + 1) // 4) ch3 = t2.channel(3, pyb.Timer.PWM, pin=pyb.Pin.board.X3, pulse_width=(t2.period() + 1) // 2)

This is what the signal looks like on a logic analyzer:

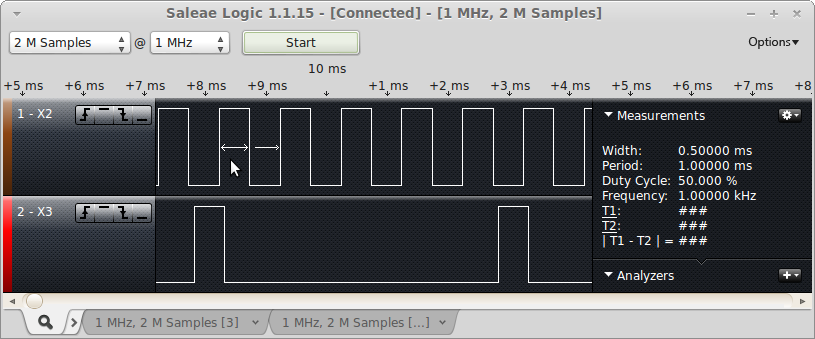

Output Compare (OC) Mode @ 1 KHz

Pin X2 is OC Mode producing a 1 KHz clock. Pin X3 is PWM at 200 Hz with a 10% duty cycle.

import pyb # setup oc_clock to be a 1 kHz clock. Since it toggles we want it to toggle # 2000 times per second to get a 1000 Hz clock. t2 = pyb.Timer(2, freq=2000) oc = t2.channel(2, pyb.Timer.OC_TOGGLE, pin=pyb.Pin.board.X2) # stup PWM to be 200 Hz with a 1 clock pulse_width t5 = pyb.Timer(5, prescaler=41999, period=9) pwm = t5.channel(3, pyb.Timer.PWM, pin=pyb.Pin.board.X3, pulse_width=1)This is what the signal looks like on a logic analyzer:

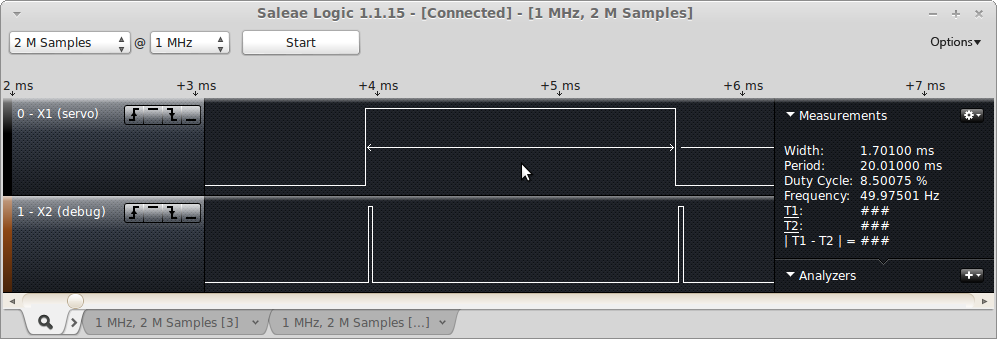

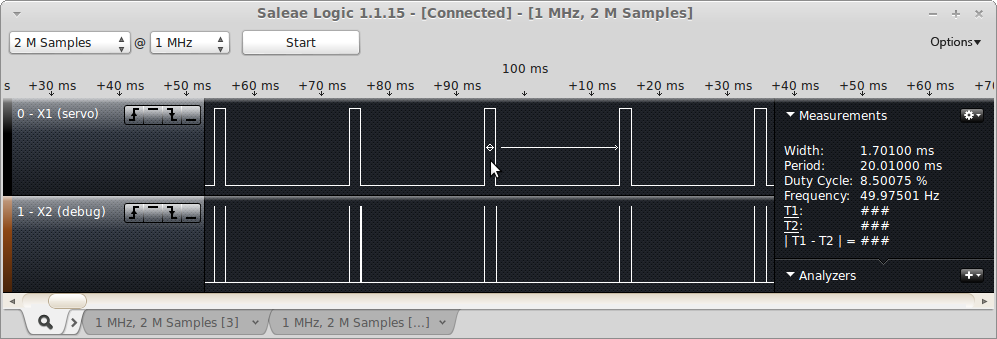

Input Capture (IC) Mode capturing a servo pulse.

Pin X1 is a servo generated pulse. There is a jumper wire connecting X1 to X4. Pin X2 is a debug pin which is pulsed from within the input capture interrupt routine.

import pyb import micropython # This script assumes that there is a jumper wire connecting X1 and X4 # For this example, we'll setup a timer in PWM mode to generate a servo pulse. # Using a prescalar of 83 gives a timer-tick frequency of 1 MHz (84 MHz / 84). # The period of 19999 gives a 20,000 usec or 20 msec period. The pulse width # is then in microseconds. servo_pin = pyb.Pin.board.X1 t5 = pyb.Timer(5, prescaler=83, period=19999); servo = t5.channel(1, pyb.Timer.PWM, pin=servo_pin) servo.pulse_width(1000) debug_pin = pyb.Pin('X2', pyb.Pin.OUT_PP) t2 = pyb.Timer(2, prescaler=83, period=0x0fffffff) ic_pin = pyb.Pin.board.X4 ic = t2.channel(4, pyb.Timer.IC, pin=ic_pin, polarity=pyb.Timer.BOTH) ic_start = 0 ic_width = 0 def ic_cb(tim): global ic_start global ic_width debug_pin.value(1) # Read the GPIO pin to figure out if this was a rising or falling edge if ic_pin.value(): # Rising edge - start of the pulse ic_start = ic.capture() else: # Falling edge - end of the pulse ic_width = ic.capture() - ic_start & 0x0fffffff debug_pin.value(0) micropython.alloc_emergency_exception_buf(100) ic.callback(ic_cb) pw = 1000 while True: servo.pulse_width(pw) pyb.delay(200) print("pulse_width = %d, ic_width = %d, ic_start = %d" % (pw, ic_width, ic_start)) pw = ((pw - 900) % 1100) + 1000

This is the output from the REPL:

>>> import ic_test

pulse_width = 1000, ic_width = 1000, ic_start = 179842

pulse_width = 1100, ic_width = 1100, ic_start = 399842

pulse_width = 1200, ic_width = 1200, ic_start = 599842

pulse_width = 1300, ic_width = 1300, ic_start = 799842

pulse_width = 1400, ic_width = 1400, ic_start = 999842

This is the logic analyzer output, zoomed in to show the debug pulses:

This is the logic analyzer output, zoomed out, to show the full servo pulse:

Last edited by Steve Holden, 2017-02-24 10:55:40